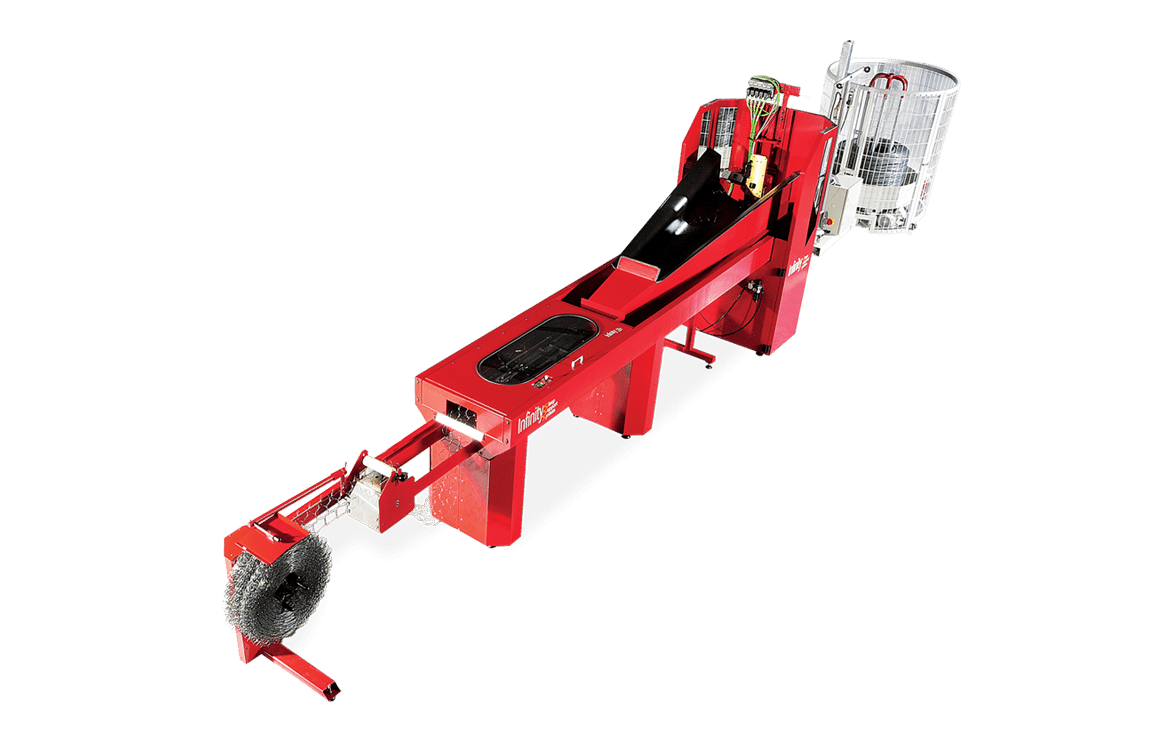

TELL ME MORE ABOUT INFINITY

The Infinity Coilers are a revelation in spring unit manufacturing. State-of-the-art processes utilise servo control coil formation. Thanks to the coilers’ innovative design, maintenance of the system and costly parts usage is reduced to an absolute minimum. No specialist operators are required – previously a major issue with spring unit manufacturing.

The Touch Screen Interface allows for simple adjustments to virtually every part of the spring. This means that mechanical adjustments to the system are virtually eliminated. It’s also possible to store multiple spring configurations within the system memory. These can then be easily accessed at the touch of a button when required.

Technical Specification 6″

Infinity Coiler System Features:

Variable Speed Servo Controlled Coil Production

Maximum Speed 65 Coils Per Minute

Uses Micro Gauge Wire

Full Servo Control

De-skilled Operation

Minimal Maintenance Costs

Coiler Technical Data (Standard Machine)

Wire Diameter Range: 1.40 mm to 1.80 mm

Spring height: 150 mm to 160mm

Coiling speed: 60 – 65 coils per minute

Swift Cage:

Designed For Swifts Weights Up To 1200kgs

Fitted With Over-Feed Sensors

Machine Voltages:

220v – 480 Volts 3 Phases + Neutral

50 – 60 Hertz

Air Requirements:

Single Feed Per Coiler 100 psi

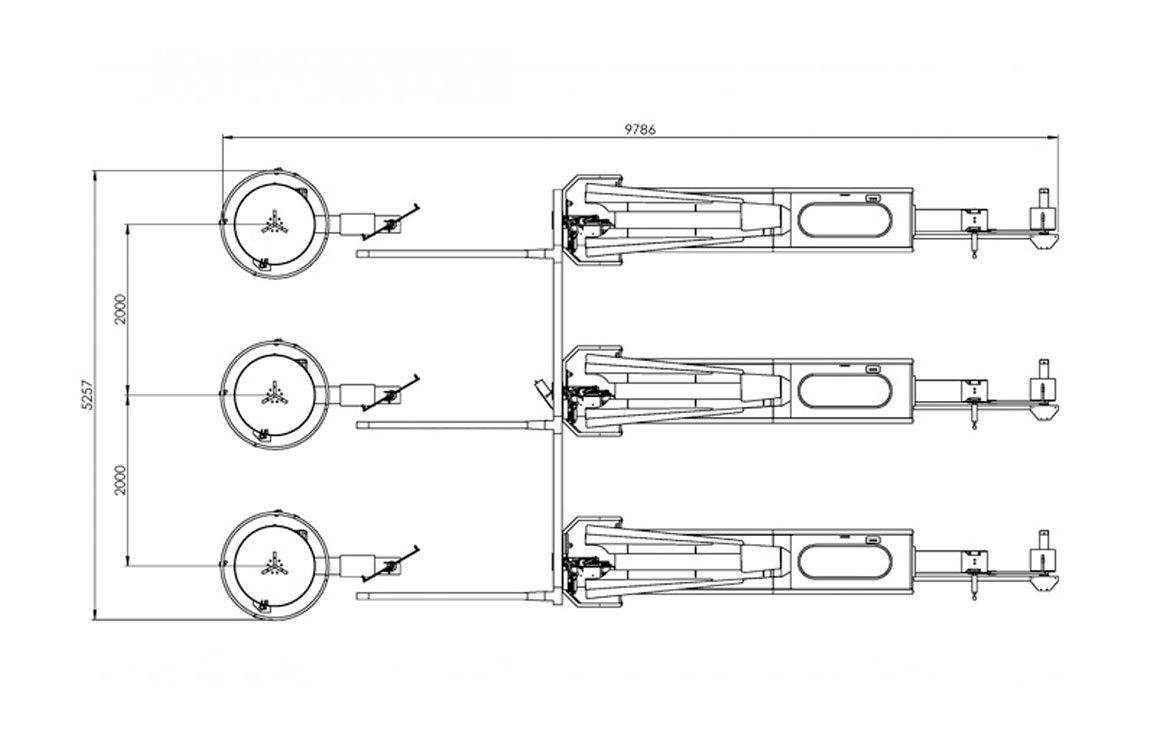

Machine Dimensions (See Gallery)

Technical Specification 7″

Infinity Coiler System Features:

Variable Speed Servo Controlled Coil Production

Maximum Speed 65 Coils Per Minute

Uses Micro Gauge Wire

Full Servo Control

De-skilled Operation

Minimal Maintenance Costs

Completes 1 roll in 45 minutes each roll containing 1900 springs

Coiler Technical Data (Standard Machine)

Wire Diameter Range: 1.90 mm to 2.00 mm

Spring height: 190 mm to 203mm

Coiling speed: 60 – 65 coils per minute

Swift Cage:

Designed For Swifts Weights Up To 1200kgs

Fitted With Over-Feed Sensors

Machine Voltages:

220v – 480 Volts 3 Phases + Neutral

50 – 60 Hertz

Air Requirements:

Single Feed Per Coiler 100 psi

Machine Dimensions (See Gallery)